Description

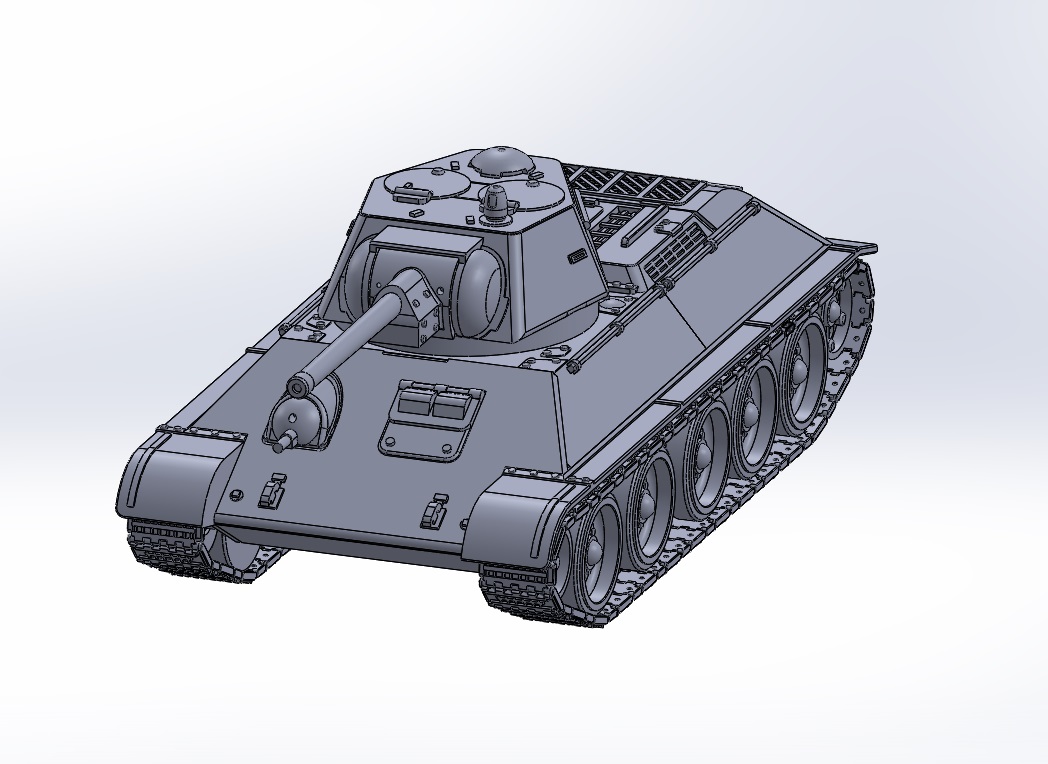

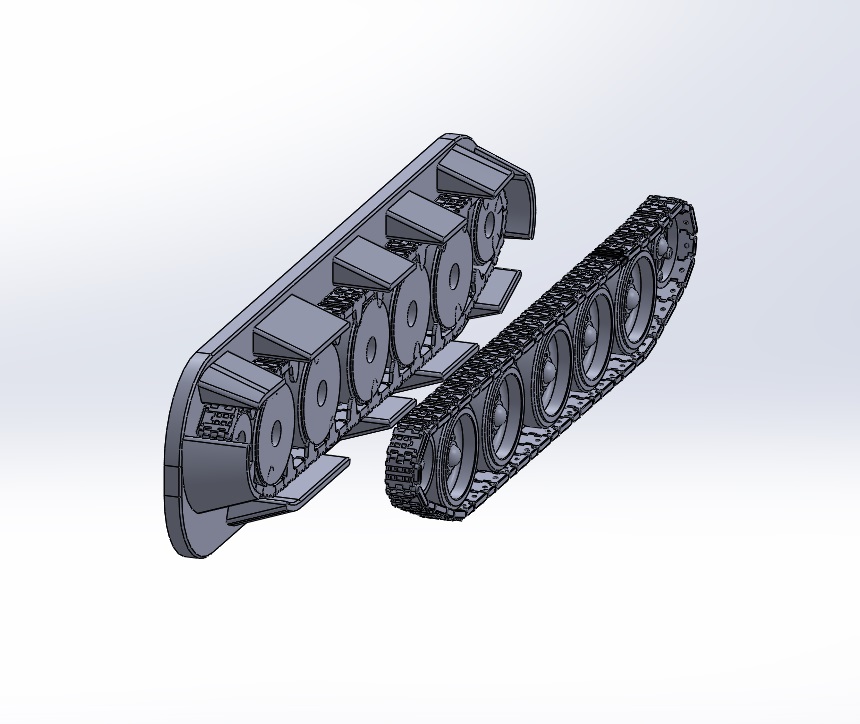

STL file for the T-34/76 assembly kit.

- Near Support Free

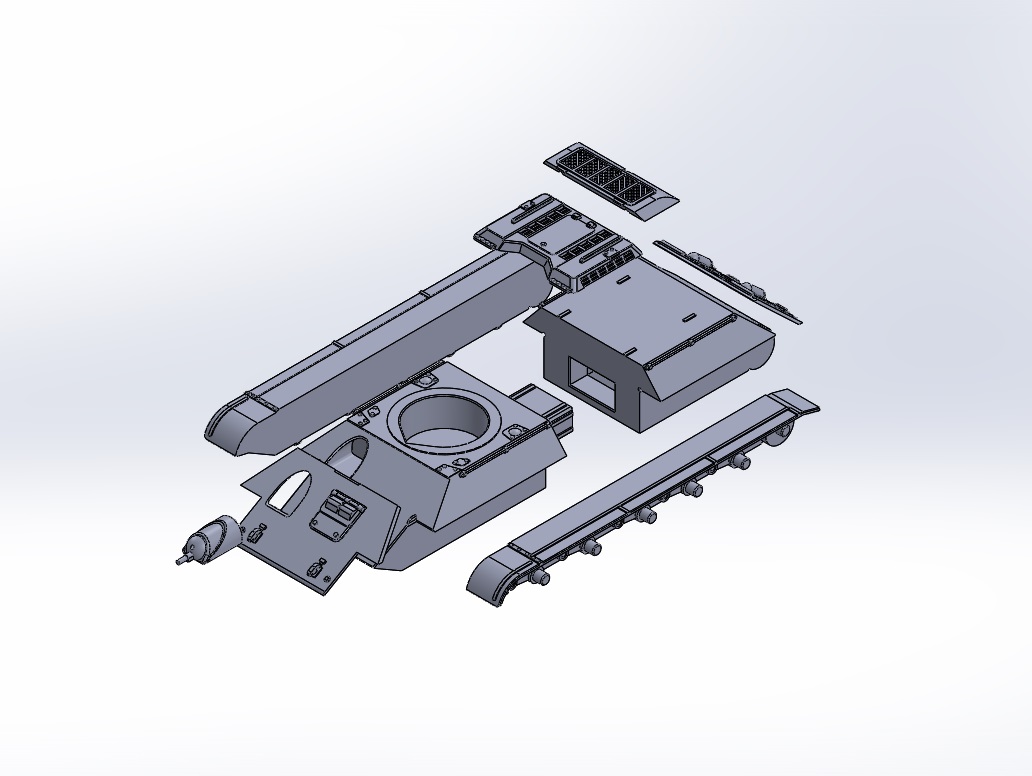

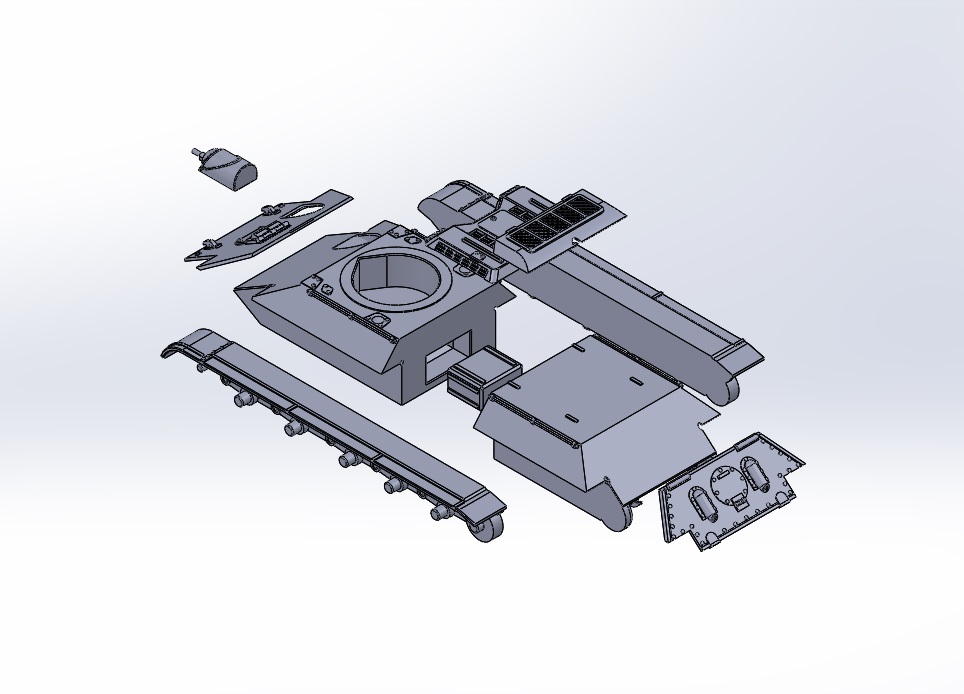

- Assembly kit: The model is designed so that every visible face has a great finish right out of the printer.

- No Gradient lines: the model is optimized to avoid gradient lines on all visible face once assembled.

- Files Scale: 28mm-1/56

Support:

- Hull: None

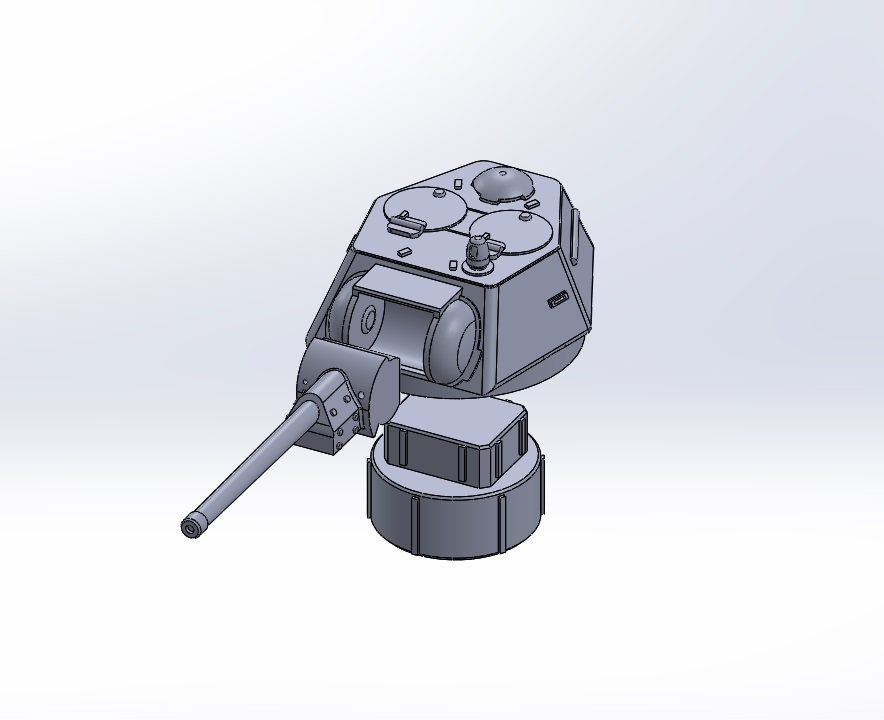

- Turret: Back of the Turret only

- Tracks: None

File Scale: 1/56